Quality Inspection Room

We have a very complete quality inspection room that can meet the quality requirements of international customers. We attach great importance to the quality needs of our customers. Therefore, we have been able to inspect from Incoming Quality Control (IQC) to finish products inspection. All of the tests data will saved completely follow the rules of ISO 90001 & ISO 13485 specifications to protect the interests of the guest.

| Name of Machine | Description |

|---|---|

| 1. Compression and Deformation Tester | Tien Jiang used compression and deformation tester for static compression to test the neoprene. Test the amount of deformation recovered, after compression in an oven at a certain temperature and a specified time to know whether the material meets product requirements. |

| 2. Durometer | Tien Jiang used durometer to measure the hardness of honeycomb, soft, hard and neoprene materials. |

| 3. Resilience Elasticity Tester | Tien Jiang used resilience elasticity tester to test the impact resistance of elastic materials and neoprene. |

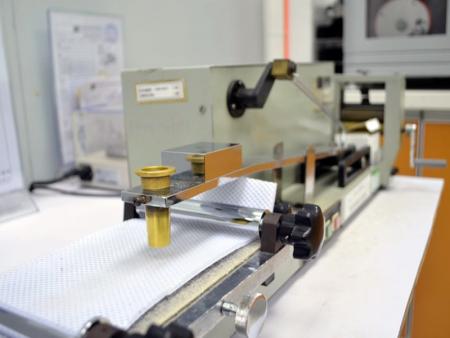

| 4. Tensile Strength Tester | Tien Jiang used tensile strength tester to test the tensile strength, elongation, tearing, peeling, shearing force, stress and sewing strength of fabrics, threads, leather, plastics (buttons), elastics and hook-and-loop fasteners etc. |

| 5. Velcro Fatigue Tester | Tien Jiang used the velcro fatigue tester to make the velcro tape (velcro tape) peel and stick repeatedly. After a certain number of times, use a tensile tester to test the strength of the peel and shear of the AB buckle. |

| 6. Crock Meter | Tien Jiang used the crock meter for testing dyed of fabrics or leather, with dry or moistened white cotton cloth, wrapped in a friction hammer, and then repeatedly rubbing the test piece clamped on the test bench, with the degree of pollution of white cotton cloth, and comparing the gray sample card to evaluate the dyeing fast Degree rating. |

| 7. Taber Type Abrasion Tester | Tien Jiang use the taber type abrasion tester to test the abrasion resistance test of fabrics and leathers. It is different from the common MARTINDALE in that the grinding wheel is use for friction. The reason is to simulate the friction with the ground during the movement. |

| 8. Salt Spray Test Machine | Tien Jiang used the salt spray test machine to test the metal surface. After coating or electroplating, test its corrosion resistance (whether it is rusted). |

| 9. Color Fastness to Washing Machines | Tien Jiang used color fastness to washing machines for testing dyed fabrics, place the sample in the test cup, after washing at the specified temperature and time, then compare the gray sample card to evaluate the color fastness of the test piece to determine whether the material meets the relevant requirements. |

| 10. Drying Oven | Tien Jiang use drying oven for drying, baking and preheating various materials, samples and products, and judging their changes after being subjected to heat (constant temperature). (Normal temperature +10°C - 300°C) |

| 11. Tumbling-Box Washing Machine | Tien Jiang use tumbling-box washing machine to simulate the phenomenon that the product does not delaminate (laminate) and the accessories fall during the washing process. (Constant temperature-normal temperature, 20°C, 30°C, 40°C) |

| 12. Color Controller Light Box | Tien Jiang used color controller light box for inspect the color of material and matching colors of raw materials or products. In the standard light source, the color of the raw materials or products can be compare to have an objective and fair judgment. (Mainly D65 lamp) |

| 13. Needle Detector | Tien Jiang used needle detector to detect metal objects hidden in raw materials, semi-finished products or finished products to ensure that there are no metal foreign bodies to harm consumers. (Such as broken needles, etc.) |

| 14. Various Inspection Tools | Tien Jiang has various inspection tools. From the left is Thickness meter, fabric density mirror, spirit level, gray label card, salt water tester, infrared thermometer, anemometer, PH meter and photometer. |

- Compression and Deformation Tester

- Durometer

- Resilience Elasticity Tester

- Tensile Strength Tester

- Velcro Fatigue Tester

- Crock Meter

- Taber Type Abrasion Tester

- Salt Spray Test Machine

- Color Fastness To Washing Machines

- Drying Oven

- Tumbling-Box Washing Machine

- Color Controller Light Box

- Needle Detector

- Various Inspection Tools